A Brief History of Body Armour

With a nationwide lockdown put in place during the set up, a recent blast test was a challenge for all concerned. After months of planning, we managed to complete the testing of some high performance concrete façade panels for Fibrobeton of Turkey. With all personnel working within the constraints of social distancing, the local hotel shutting down on us, the customer and visitors prevented from attending, there were more challenges than usual. Working with both DNVGL and OTS Ltd we prevailed, completed the test and captured the data.

Personal armour has always a trade off of protection from the prevailing threat, mobility, cost, weight and functionality for daily use such as how compatible it is with all the other kit a soldier may have to carry and then fight with.

In antiquity the foot soldier would be protected on his upper body with sectioned metal armour, the focus being on wielding and be protected from bladed weapons. Shields were common and depending on the style were cumbersome and heavy for extended use. The lower half of the body was less protected – mobility being deemed to more important.

In medieval times the wealthy classes moved towards a more complete coverage of the body. General mobility would be mostly covered by being on horseback, but dismounted combat was still a feature. The amour was complex in design and often ornate, a status symbol as well providing protection. Visibility and hence situational awareness, dismounted mobility, heat dissipation and cost were played down in favour of all over protection.

The advent of effective firearms changed everything. The suit of armour was now obsolete and for many years there was no practical means of protection that was light enough to do the job. Helmets did make a large scale reappearance during the First World War, but aside from some improvised efforts from the likes of Ned Kelly, the emphasis changed to fire and manoeuvre and more often combat was undertaken at a distance.

In the post war period there was a very gradual shift. Technology improved and the public tolerance for casualties declined. ‘Flak jackets’ providing modest protection appeared and then became enhanced with relatively small ballistic plates mounted to cover the heart. This was the style of armour used in ‘The Troubles’ in Northern Ireland and deployed widely in the First Gulf War.

Technology marched on and fatalities became political poison. Bodies were now repatriated back from afar to the UK. Regular coverage on the news literally brought home to the public the consequences of conflict.

In the UK this resulted in the introduction of the Osprey body armour system. This featured much larger and higher performing ballistic plates to front and rear with option plates for the sides. Coverage of the vital organs was much more effective but the burden of weight went up, mobility was impacted and heat dissipation became an issue in warmer climates. The cost went up but this was not an issue for the wearer. In parallel to ballistic torso protection, materials technology also provided more choice for lighter helmets. Here again there were trade-offs and compromises to be made for weight and situational awareness. This philosophy of increasing protection through increased coverage was adopted across other NATO nations who were under similar pressures to reduce fatalities and casualties wherever possible.

The Osprey system has since been replaced by Vertus but the coverage aspect remains the same. The changes are based on weight and integration for better biomechanical support.

The generic construction of hard armour inserts is a ceramic front face with a moulded fibre reinforced composite backing. The ceramic causes the incoming bullet to be broken up and energy is dissipated through cracking of the ceramic. The composite material backing is designed to capture the fragments of the bullet. Further energy is absorbed through deformation of the backing and through delamination of its structure.

The backing composite is a much lower density than the ceramic. This interface causes a significant proportion of the incoming shockwave to be reflected back into the ceramic and away from the body. The coverage of these modern plates and the materials used has created the situation in which general issue infantry body armour is providing protection from shockwaves that is much more like the capability of dedicated EOD suit plates. Protection from blast to the torso on the battlefield has undergone a revolution. This though has its consequences.

Shifting the Causes of Injury and Death

Towards a Viable Surrogate

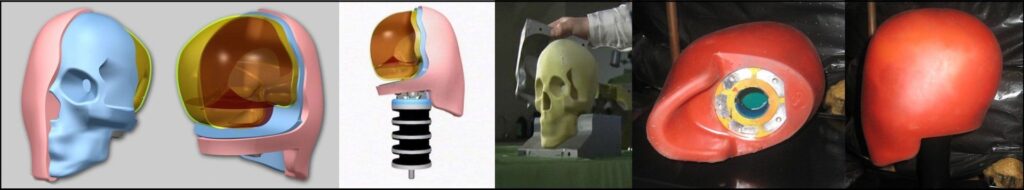

It would be most useful for this process to have some form of surrogate head that features the layers of the skull and some of brain that behaves as would an actual skull and brain but in a predictable, bio-fidelic, and repeatable manner. This surrogate should facilitate some form of measurement system that has the right response in terms of measurement sampling rate and resolution.

The starting point for looking into this was the Frangible Surrogate Head produced by our colleagues in Australia. We had previously contributed to the later development stages of their Frangible Surrogate Limb which became a NATO approved tool for testing landmine protection footwear.

The Frangible Surrogate Head (FSH) was actually developed for a Discovery Channel documentary ‘Inside the Target Car’ which investigated the assassination of President Kennedy. The purpose of the FSH was to behave correctly under ballistic impact in terms of skull fracture and surrogate brain material – artificially coloured for clarity. With the correct bullet striking the head at the accepted angle, velocity and location on the head, the distribution of matter was a good match for that observed at the scene.

Testing Times

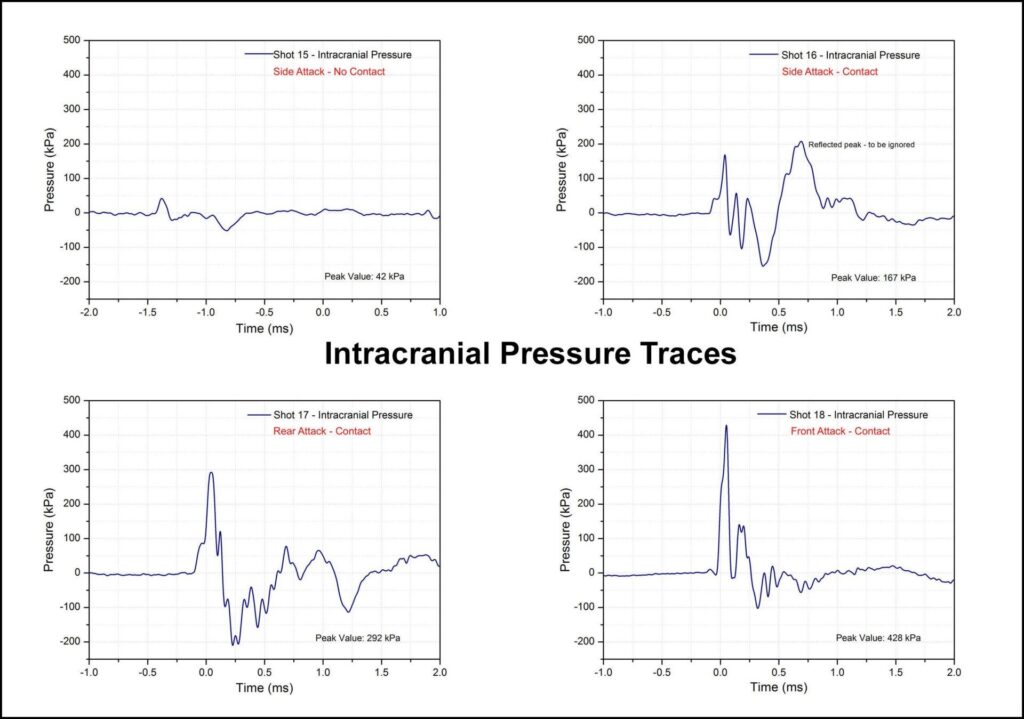

The cavity within the FSH was cast with ballistic gelatine at a 10% concentration, which has been used elsewhere as a homogeneous brain surrogate. Into this, through the rear of the base of the skull, were inserted two needle pressure gauges, their tip reaching the centre of the ‘brain’.

The FSH was set on a Hybrid III neck (more of which later) and then fitted with the first of a series PASGT NIJ IIIa helmets.

Variables: Two key variables were examined during the test series.

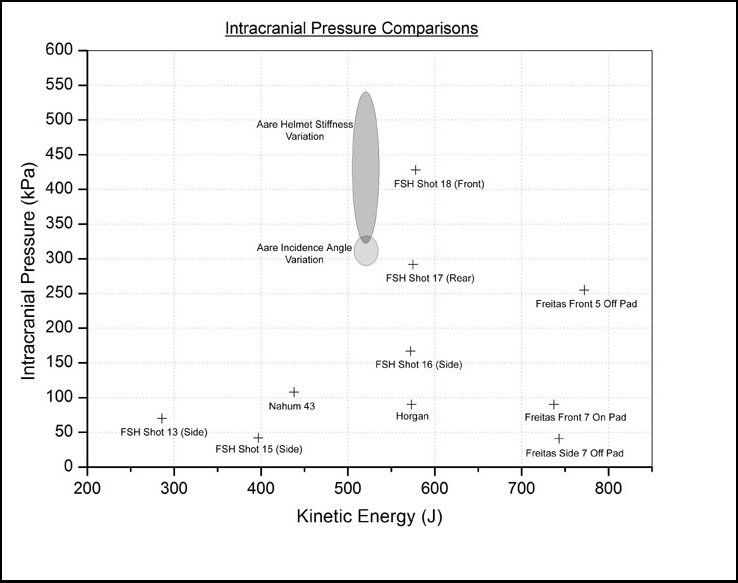

The first was altering the kinetic energy of the 9mm ball rounds by adjusting the cartridge fill.

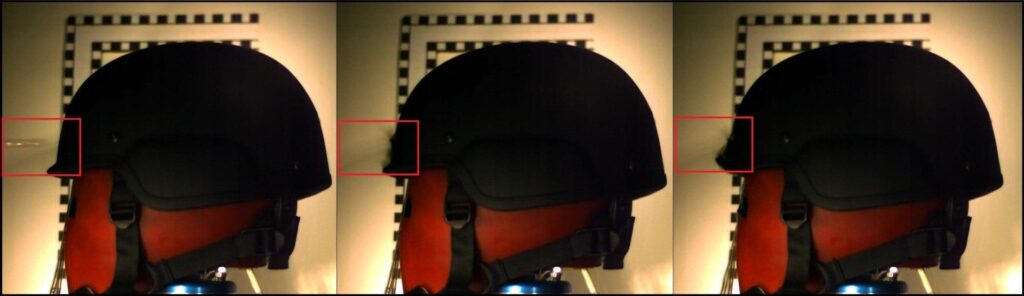

The second was the impact point on the helmets. The design of the PASGT, like many helmets, does not have a constant spacing between helmet shell and the head. The sides, by making room for the ears, have the greatest separation. The rear of the helmet is closer and the front has the smallest gap. Given a similar level of local shell deformation, the likelihood and degree of mechanical impact of the helmet on the head will therefore vary, as should the consequential internal pressure.

For all the technology employed, including high speed cameras, the means of determining whether or not contact had been made between helmet shell and head was very old school but reliable. The inside of the shell in the impact area was smeared with a red wax – otherwise known as lipstick. After each test the head was inspected for any transfer that resulted from direct contact.

The ‘Frangible’ element of the FSH, as demonstrated in its TV use, is the cracking and even break up of the skull under sufficient loading. To keep track of FSH integrity for each test and to see if such threshold levels were reached, the FSH was x-rayed after each event.

The basic thrust of the test series was to increase the kinetic energy of the bullets fired to the side of the helmet until a contact and /or a significant internal pressure spike was observed. This same kinetic energy was then used to investigate impacts to the rear and then the front of the helmet.

Outcome And Future Options

The tests illustrate the need for the end user to make a careful selection of helmet shape. A larger, wider helmet with significant gaps between shell and head all round is the best option for isolating the skull from back face deformation and transmitted shockwaves. This runs counter to current ‘fashion’, especially as observed within the SF community, with cut back and tight fitting helmets for which operational awareness is deemed to be more important.

Within the constraints of the tests, it can be seen that the FSH has potential as a tool in this field of research.

For ballistic testing there may well be little that would need refining. For blast tests there are some obvious limitations and options for improvement.

• The current FSH does not feature any channels for blast overpressure to enter or get closer to the brain such ear canals, nasal sinuses, eye sockets or a mouth. A more refined structure would be help with this.

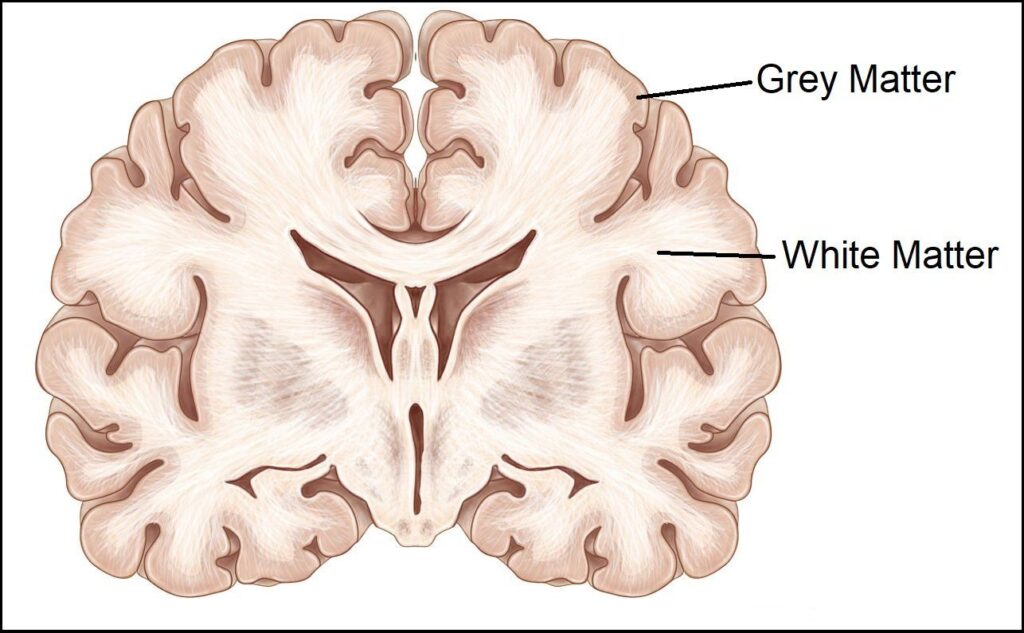

• A homogenous brain was achieved by casting though the base of the FSH. If it was felt that a dual density brain surrogate was required to simulate both white and grey matter, this may need to be cast separately, which would in turn require a head-form that could be opened up sufficiently, perhaps compromising its structural integrity and biofidelity.

• The possibility of placing markers into the outer layers of the surrogate brain and a detection matrix on the inside of the skull would create the possibility to measure translation and rotation of the brain within the skull for higher displacement, longer duration events as found in vehicle crashes or in sports.

• The Hybrid III neck is optimised for the car crash environment. For other applications such as for blast testing it is recognised as being too stiff and does not respond in a representative timescale. Looking into the more compliant neck could form part of any improvement.

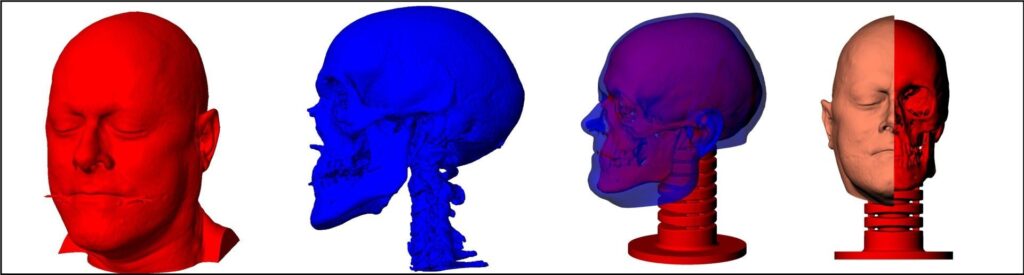

We have been helped with detailed 3d imagery of a head and skull which has been used as starting point for mounting on a mechanical neck which at the moment this has the dimensions of the Hybrid III. Traces of the owner’s rather distinguished moustache are visible in the basic head scan.