Sub-Station Blast and Fragmentation Protection Concept

Reacting to incident report with similar equipment at a different facility, a customer had a requirement to protect against the blast and fragmentation from a ceramic insulator failing in a substation.

As with all such infrastructure, shutting it down to carry out the replacement of the suspect items would have implications for the operation of the wider facility. They were interested in a solution that minimised the need for such a shutdown, or better still avoided it all together.

The customer had no specific threat data with which to work, so we referred back to an earlier project with an international customer. They had performed range tests to deliberately fail similar ceramic insulators to record the mass and speed of the resulting fragments. This gave us a kinetic energy to compare with established ballistic threat data.

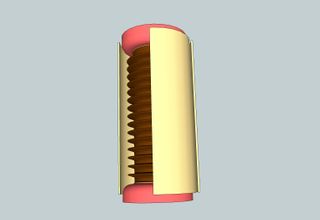

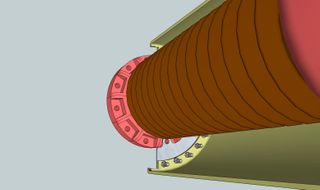

The earlier project required a solution that would encase new insulators to protect adjacent equipment by stopping the threat at its source. The design of the particular insulatorsin question offered mounting points at their top and bottom. Adaptor plates were designed and overlapping moulded ballistic composite sections were used. The stepped overlap concept prevented any line of sight threat from fragments while still allowing airflow and heat dissipation as required around the equipment. The composite mouldings were non-conducting so the electrical insulation requirement was maintained.

Although it provided some useful data, this integrated approach would not be acceptable for the new sub-station issue.

A site visit and meetings with the customer to discuss access, work spaces, available footprint, timelines and budgets steered us towards a suitable solution.

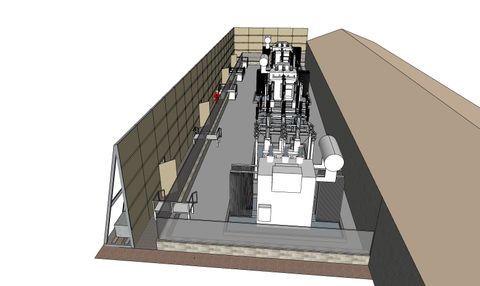

Proposed Solution:

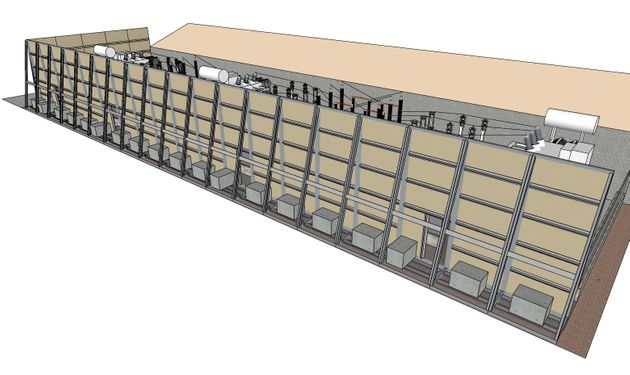

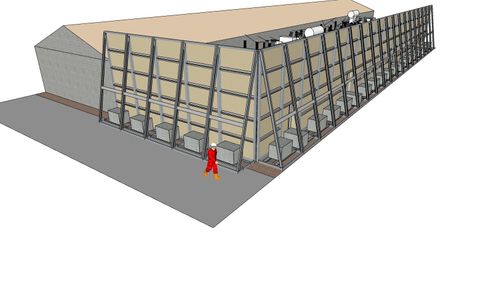

The protection of the substation was to be along two sides its capacious compound. Access into the different parts of the compound was via gates and steps. This had to be maintained once the protection was in place.

The customer had specified the height of the system to provide line of sight protection to adjacent buildings and equipment. Standard 2440 x 1220mm composite ballistic panels were employed, the thickness and material being selected to match the kinetic energy of the threat. Mounting holes were to be cut by waterjet and each panel sprayed with a coating to seal against the weather and UV.

The mounting frames were a modular design that would be assembled on site, away from the substation itself. Once complete, the ballistic panels could be bolted on and the each assembly moved to the sub-station and positioned without affecting its ongoing operation. Adjacent protection assembles would be bolted together and concrete blocks added to the bases to stabilise for wind loading. Planning estimates showed that once the kit of parts was on site, the protection would be in place in two days.

Access to the stairs and gates was achieved by reorienting the lower composite panels and using one as a door.

Easy to install, the system is also easy to fully or partially relocate or remove for fuller access to the compounds for engineering works.

This design concept is easily transferable to other substations, its size and protection level adaptable to the user’s specific requirements.